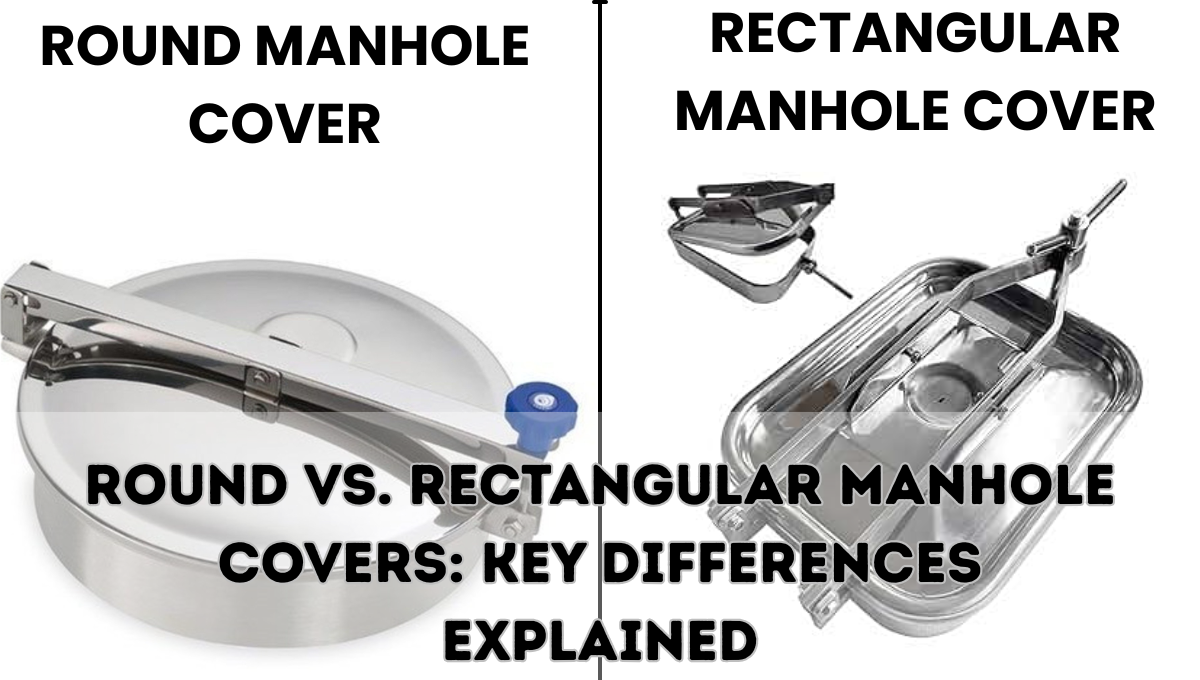

Steel tanks are the base of most chemical operations, from production to preservation. Many industries must install these tanks to achieve safe and precise results, whether it involves food processing, fermentation, or any other operation. Steel, cast ductile iron, and various alloys are used for the production of not only tanks but also their manhole covers. These are the opening covers that allow workers to conduct operations such as mixing, inspection, and various similar tasks. Since there are circular and rectangular manhole covers in stainless steel tanks, how do they differ in terms of performance? Let’s find out. You will get a detailed comparison between them, which will help you decide which one is suitable for your tank.

The first type is circular, which is common in industries due to its numerous advantages. What makes these manhole covers suitable for many industrial tanks is the reasons below.

Because of the circular shape, they have an equal distribution of pressure on the tank’s manhole. The tank pressure remains stable because the circular shape eliminates the risk of leakage. Tank operators achieve anti-leak results since the circular shape remains consistent from all sides, and the seals provide a tight grip. Especially in mixing and fermentation processes, circular covers offer efficient results.

There is a risk that the tank’s manhole caps may fall into the tank. However, circular types have no specific angle like rectangular ones, which could lead to falling through the opening. This is the second biggest advantage of a circular shape because it prevents mishaps like dropping the cover inside the tanks.

Tanks that require small openings benefit from circular covers. The reason is that circular manhole covers provide better control in the opening and closing process. During the production and mixing operations inside the steel tank, operators can easily open the covers with minimal effort. This is why small openings with circular covers make the mixing and inspection operations easier.

The seal must be tight to maintain consistent pressure and temperature. The preservation operations require this function, and a circular cover provides high support for it. The grip they retain, along with seals, leaves no chance for steam, liquid, or gas to escape. Thus, the optimum conditions are achieved by the tank operators in large operations. Food, chemicals, and beverages receive full support in these operations in terms of pressure consistency.

If the sealing is accurate, there will be no changes in the preservation. It is an essential function that requires full support from tank manhole covers. Circular covers provide balance in it since they have the same performance from every direction. Installing these covers is also more convenient since they don’t need any angular adjustment. All a worker has to do is place them and tighten the bolts.

Then there are rectangular steel manhole covers for tanks. They are also common in industrial applications. However, they provide slightly different advantages, which are mentioned below.

When there is a need for angular installations, one must opt for rectangular covers. They meet the requirements in terms of angular compatibility. Since circular covers cannot assist in these applications, one has to opt for rectangular types. Tanks that need openings in the corners or at the bottom need non-circular manhole covers.

Some tanks require specific openings due to the activities they need to accommodate inside. Additionally, the inspection processes differ from standard methods. These processes make the need for rectangular covers.

In some tanks, workers must enter for maintenance. A circular cover does not have enough space for a worker to get inside. This is why a rectangular cover works the best for it. Its wider side enables the worker to step easily inside the tank for cleansing and repair activities. The width of the opening is larger than usual. These are large tanks that require deep cleansing to prevent bacterial growth and corrosion.

A circular opening cannot create much space for a worker to enter, since human shoulders are broad. A rectangular opening allows enough space for this process. Then any worker can step inside safely.

Likewise, irregular-shaped and wide tools can’t pass through circular openings in a tank. They need a more expansive space to get inside. A rectangular opening is the right choice because its wider side allows the tools to be easily accessed. Workers can adjust the tools to get them inside the tank for the cleansing process. Some devices have irregular designs, which means you need non-circular openings for them.

Space efficiency is necessary when you know that tanks require frequent maintenance. A circular opening cannot provide much space for it. That means a rectangular opening will be required. Usually, these rectangular covers provide space efficiency by adjusting to flat angles. For instance, a tank is placed near the wall, and you will have to arrange the opening for mixing activities. You will need to use a rectangular opening because it allows the angle to match the flat corner. It will also save space from getting wasted by providing accurate angles of cover.

Both types have their pros and cons. The circular one maintains a more balanced design to keep the seals tight. It helps them maintain a constant pressure level inside the tank. Likewise, it is easy to adjust the circular cover because it is the same from all directions. On the other hand, rectangular covers are suitable for angular spaces. They provide space efficiency by aligning with the flat surface or corners of the tank. Also, rectangular covers allow workers and their equipment to get inside the tank easily for maintenance and operational activities. It depends on your requirements, and you will have to choose based on their pros and cons.

Steel tanks are the base of most chemical operations, from production to preservation. Many indus

READ FULLIn today's fast-paced world, industries are constantly evolving and implementing new technologies

READ FULL